Introduction

【On the basis of the hand-operated flat knitting machine of the original, in order to realize the automatic control operation instead of manual operation of the electrical installation, motor drive system, microcomputer control system, complete the automation of flat knitting machine.】

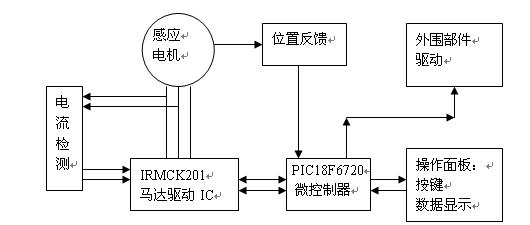

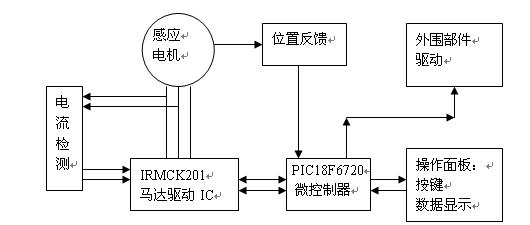

【In order to realize the smooth drive motor, the main control device of IC as a motor drive control with AC servo advanced, with micro controller as the basis to design a controller of the flat knitting machine. The controller complete motor cross machine variable frequency drive, system parameter setting, woven pattern of management, process control and other functions.】

The system block diagram

Function characteristics

◆【Motor frequency conversion driving, the microcomputer process control, constant torque output.】

◆【Working voltage: AC 220V ± 20% 50HZ】

◆【The motor output power: 260W】

◆【Noise: the whole machine is the average noise is less than 75dB (A)】

◆【Working temperature: 10-40 ℃】

◆【Needle: 1, to 3, 7, 5, 9, 10, 12, 14, 16, 18 model】 ◆【Speed: 8 speeds optional, a maximum speed of 1.8 m / s.】

◆【Color changing device: free switch and】

◆【Stop device: antenna, head, 0.5 seconds stop】

◆【A needle adding device: around can be separately don't control】

◆【Write protection function: can choose to lock, lock protection program】

◆【Head positioning error is less than 1 needle weaving amplitude adjustable】

◆【Liquid crystal display, simple operation.】

◆【Weaving patterns can be set up in advance, to meet the different requirements】

◆【Due to limited space, if you wish to design the program to do a more detailed understanding, can directly send mail to Tech@xinmandz.com mail request, must add written company, contact, telephone, our staff will be one one reply】